WE WORK FOR

YOUR SUCCESS

The company AK Kunststoffspritzguss is a family owned business in the injection moulding industry. We producing high-quality technical parts, which will be used in the medical technique, houshold appliance, electro industry and cosmetics.

We always use the following principles:

The quality of the produced parts and the satisfaction of our customers comes first!

If high quantity, low quantity or trial production we always have fair prices!

WE WORK FOR

YOUR SUCCESS

The company AK Kunststoffspritzguss is a family owned business in the injection moulding industry. We producing high-quality technical parts, which will be used in the medical technique, houshold appliance, electro industry and cosmetics.

We always use the following principles:

The quality of the produced parts and the satisfaction of our customers comes first!

If high quantity, low quantity or trial production we always have fair prices!

WE WORK FOR

YOUR SUCCESS

The company AK Kunststoffspritzguss is a family owned business in the injection moulding industry. We producing high-quality technical parts, which will be used in the medical technique, houshold appliance, electro industry and cosmetics.

We always use the following principles:

The quality of the produced parts and the satisfaction of our customers comes first!

If high quantity, low quantity or trial production we always have fair prices!

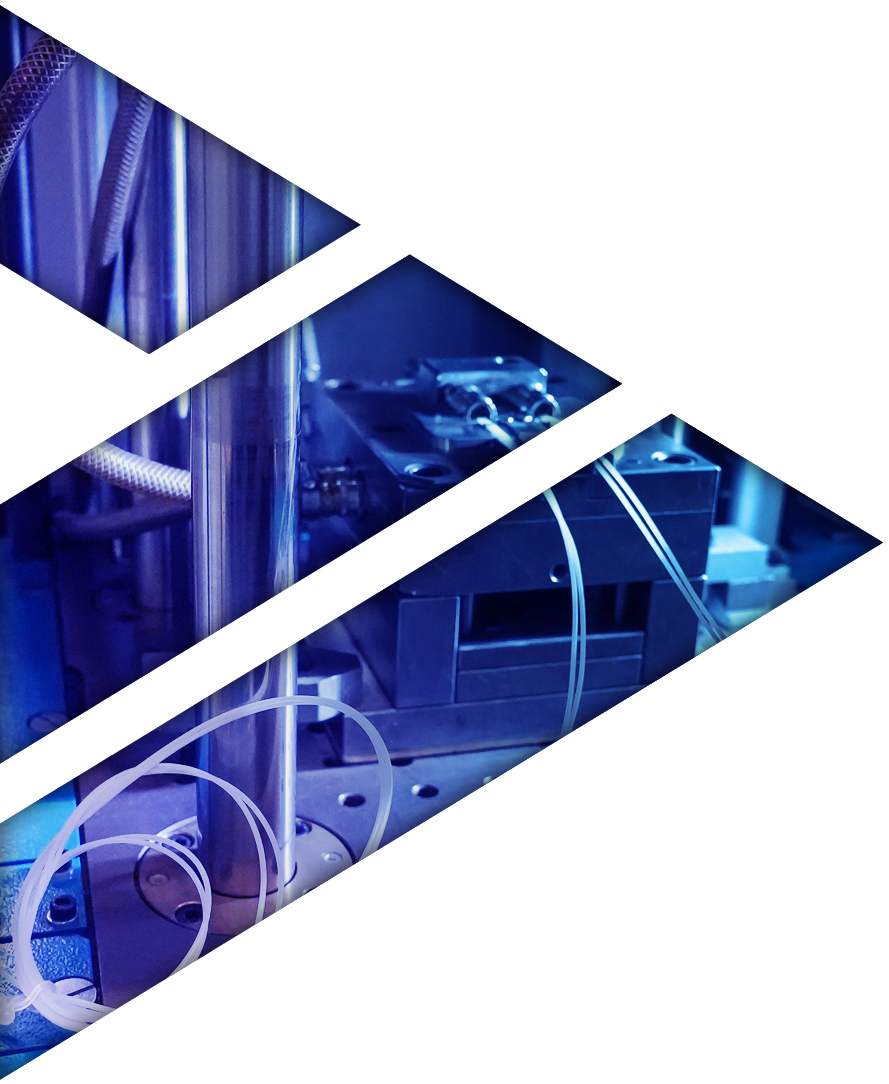

INJECTION MOULDING

REDEFINED

With our modern injection moulding machines, with clamping forces from 35 tons till 210 tons,

we are able to produce until a maximum shoot wight of 330g (PS).

All our injection machines are fitted with a sprue picker / robot system.

Resin Handling:

If necessary our raw materials can be dried in our central dryers. All our injection machines are connected with our vacuum conveyor system. Respective to the used formulation colorbatches or additives can be added by using “Minicolor” dosage systems.

Production Surrounding:

The plastic parts that we supply are mainly used in medical technology and the cosmetics sector.

Our production department therefore upholds high production standards:

– Certification in accordance with DIN ISO 9001

– Hygiene management in accordance with HACCP

– Dust-free production environment with continually filtered air

– Batch traceability throughout

– Access authorization for employees regulated via RFID cards

INJECTION MOULDING

REDEFINED

With our modern injection moulding machines, with clamping forces from 35 tons till 210 tons, we are able to produce until a maximum shoot wight of 330g (PS).

All our injection machines are fitted with a sprue picker / robot system.

Resin Handling:

If necessary our raw materials can be dried in our central dryers. All our injection machines are connected with our vacuum conveyor system. Respective to the used formulation colorbatches or additives can be added by using “Minicolor” dosage systems.

Production Surrounding:

The plastic parts that we supply are mainly used in medical technology and the cosmetics sector.

Our production department therefore upholds high production standards:

– Certification in accordance with DIN ISO 9001

– Hygiene management in accordance with HACCP

– Dust-free production environment with continually filtered air

– Batch traceability throughout

– Zutrittsberechtigung geregeld über RFID-Mitarbeiterausweise

– Certification in accordance with DIN ISO 9001

– Hygiene management in accordance with HACCP

– Dust-free production environment with continually filtered air

– Batch traceability throughout

– Zutrittsberechtigung geregeld über RFID-Mitarbeiterausweise

PROCESSES

‘WE WORK FOR YOUR SUCCESS’ and do so from the outset.

From the design of the injection moulding tool and its acquisition and the development of the corresponding production process through to development suitable shipping packaging.

1s/2s-moulding

silkscreen / pad printing

hot stamping

varnish

assembling of from us produced parts

PROCESSES

‘WE WORK FOR YOUR SUCCESS’ and do so from the outset.

From the design of the injection moulding tool and its acquisition and the development of the corresponding production process through to development suitable shipping packaging.

1s/2s-moulding

silkscreen / pad printing

hot stamping

varnish

assembling of from us produced parts

LOGISTIC

Respective quantity and part dimensions we deliver by UPS, own vehicles or by forwarder.

You are using own load carrier?

This is also no problem for our side. We do the whole logistic for in production used load carrier. Of course including pallet account.

For parts who need a high availability, we can run the production including an security stock.

TOOLING

All of our new moulds we produce at our well experienced mould makers. For continuously high quality we set there on an long term partnership.

For all moulds included. The manufacturing surveillance including reporting to the customer, if required.

LOGISTIC

Respective quantity and part dimensions we deliver by UPS, own vehicles or by forwarder.

You are using own load carrier?

This is also no problem for our side. We do the whole logistic for in production used load carrier. Of course including pallet account.

For parts who need a high availability, we can run the production including an security stock.

TOOLING

All of our new moulds we produce at our well experienced mould makers. For continuously high quality we set there on an long term partnership.

For all moulds included. The manufacturing surveillance including reporting to the customer, if required.

PLASTICS

We use a variety of technical plastic resins.

Such like unreinforced, reinforced, mineral filled till flame retardant kinds.

ABS

Novodur / Sinkral

PA6 / PA66

Saxamid / Ultramid

PBT

Valox / Crastin

PBT+ASA

ULTRADUR S

SMMA

NAS21

PC

Lexan

ABS/PC

BAYBLEND / XANTAR

TPU

Estane

TPE

Allruna / Evoprene

PARA

IXEF

PLASTICS

We use a variety of technical plastic resins.

Such like unreinforced, reinforced, mineral filled till flame retardant kinds.

RESIN /

TRADE NAME

ABS

PA6 / PA66

Novodur / Sinkral

Saxamid / Ultramid

PBT

PBT+ASA

SMMA

PC

ABS/PC

TPU

TPE

PARA

ULTRADUR S

PBT+ASA

NAS21

Lexan

BAYBLEND / XANTAR

Estane

Allruna / Evoprene

IXEF

PLASTICS

We use a variety of technical plastic resins. Such like unreinforced, reinforced, mineral filled till flame retardant kinds.

RESIN / TRADE NAME

ABS

Novodur / Sinkral

PA6 / PA66

Saxamid / Ultramid

PBT

Valox / Crastin

PBT+ASA

ULTRADUR S

SMMA

NAS21

PC

Lexan

ABS/PC

BAYBLEND / XANTAR

TPU

Estane

TPE

Allruna / Evoprene

PARA

IXEF

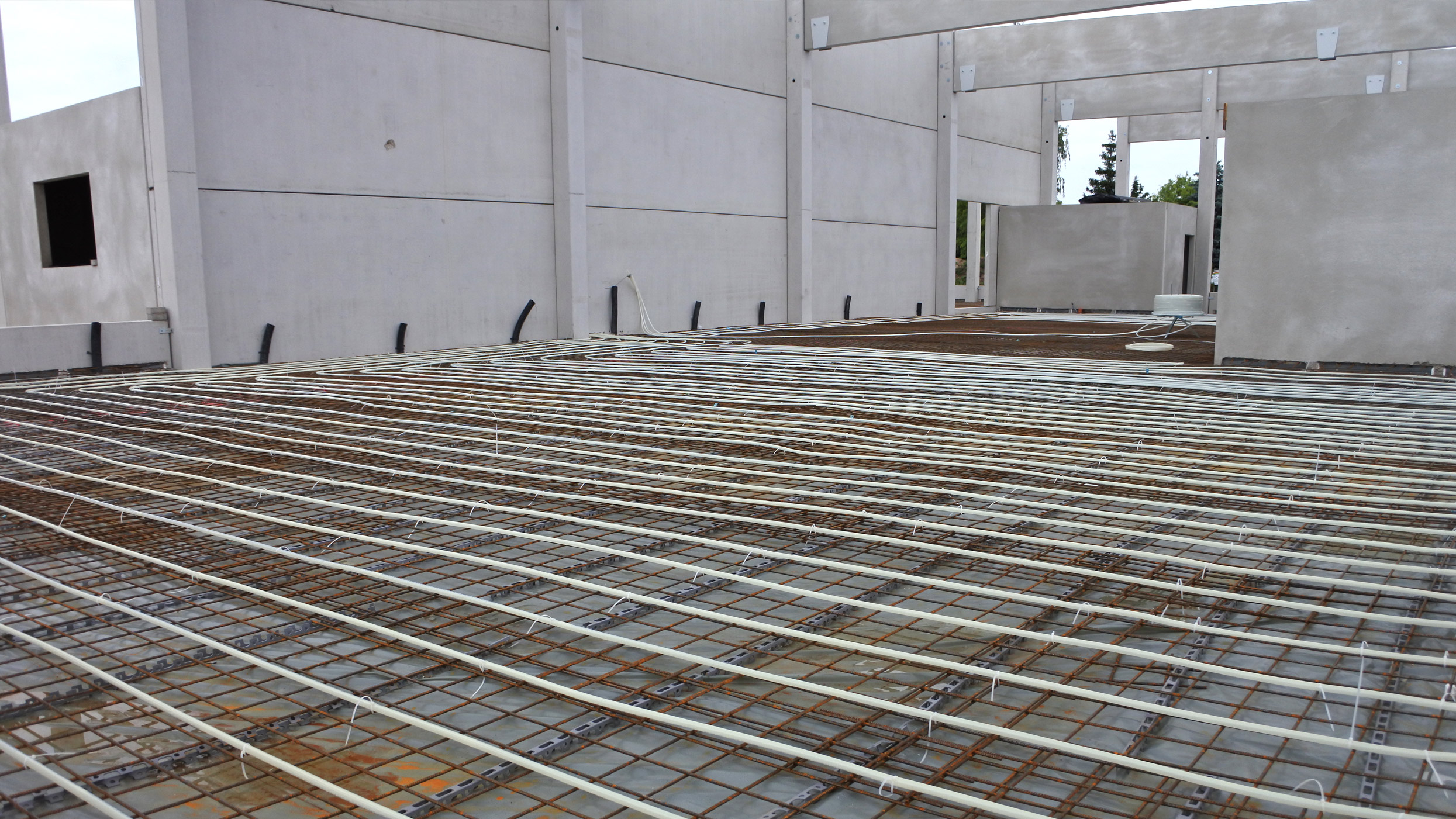

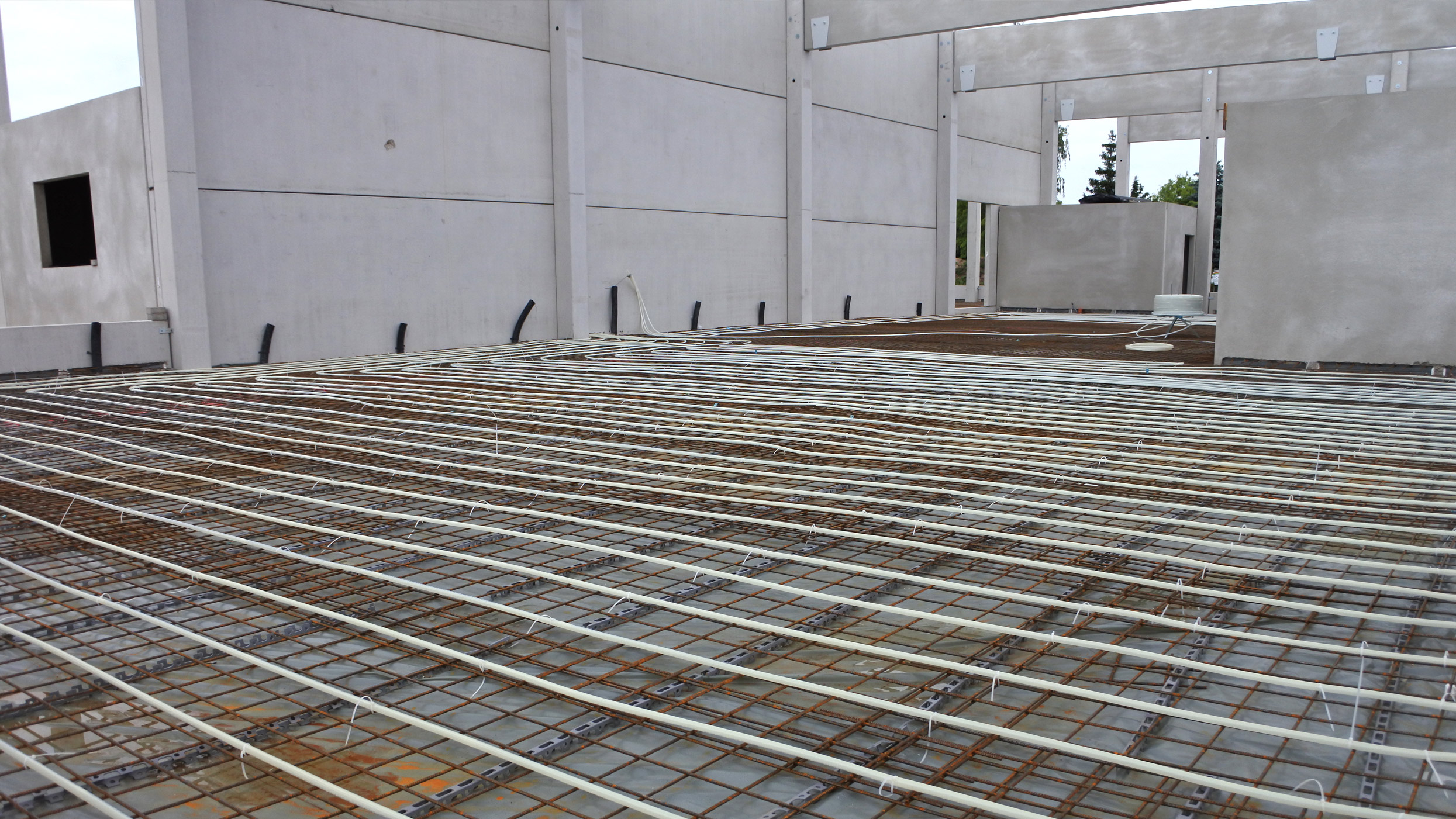

ENERGY CONSCIOUS AK

Sprues are milled directly at the injection moulding machine and transported back to our warehouse. In this way the correctly sorted mill materials are available to us as recompounds for various applications. Mill materials that cannot be re-used in our own production are sent to recycling companies. The waste heat that is created in the injection moulding process is used to heat our entire building and is thus re-used in an environmentally friendly and sustainable manner.

MATERIALS

Re-use of granulate residues and molten granulate

ENERGY

Consistent use of waste heat from the cooling water circuit and the exhaust air

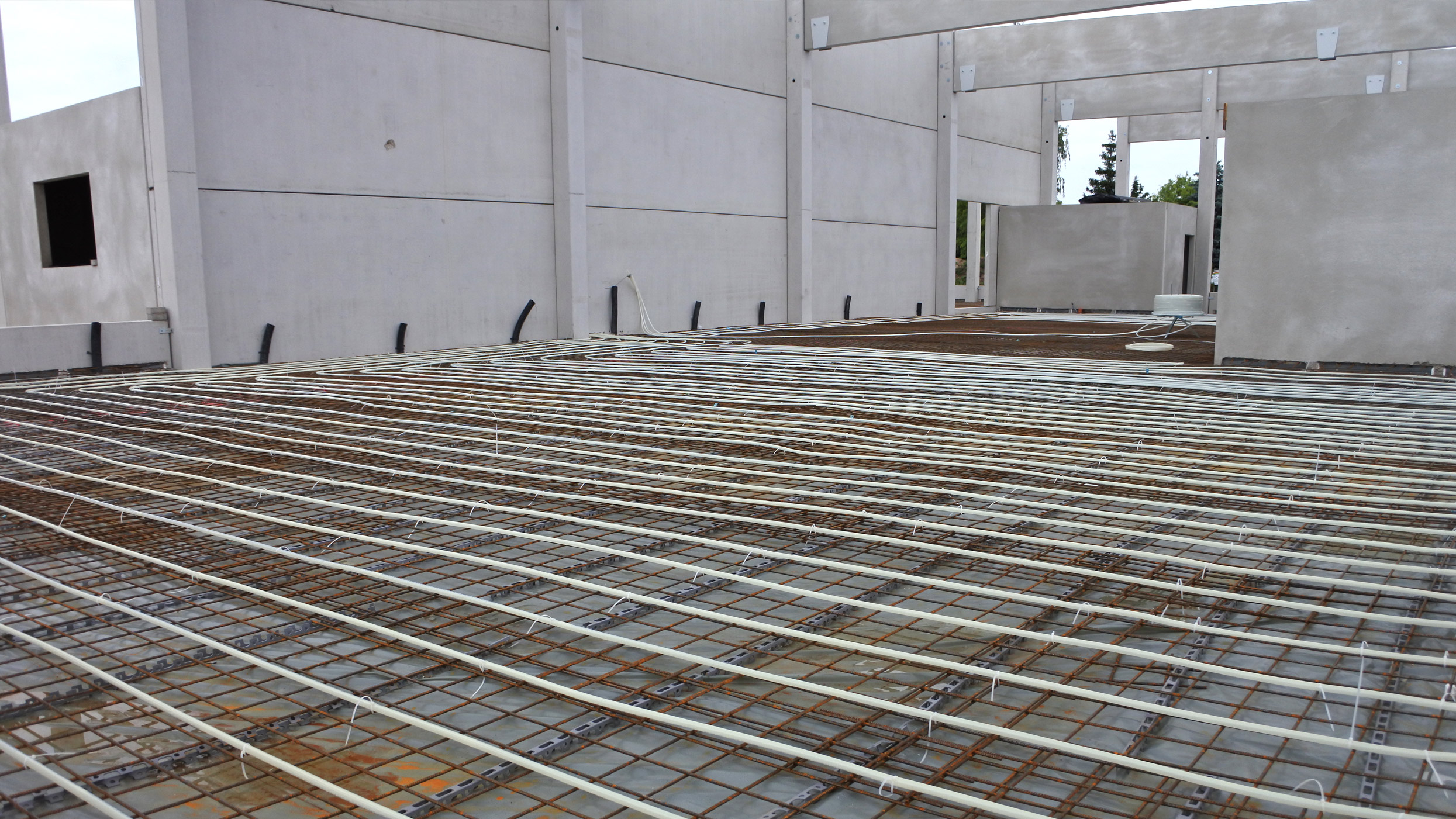

Underfloor heating was fitted throughout our production halls for the effective heating and temperature regulation of our operation.

The more effective use of existing energy saves our environment. This is why we have installed the most modern technology in order to be able to use waste heat from production more effectively.

ENERGY CONSCIOUS AK

Sprues are milled directly at the injection moulding machine and transported back to our warehouse. In this way the correctly sorted mill materials are available to us as recompounds for various applications. Mill materials that cannot be re-used in our own production are sent to recycling companies. The waste heat that is created in the injection moulding process is used to heat our entire building and is thus re-used in an environmentally friendly and sustainable manner.

MATERIALS

Re-use of granulate residues and molten granulate

ENERGY

Consistent use of waste heat from the cooling water circuit and the exhaust air

Underfloor heating was fitted throughout our production halls for the effective heating and temperature regulation of our operation.

The more effective use of existing energy saves our environment. This is why we have installed the most modern technology in order to be able to use waste heat from production more effectively.

ENERGY CONSCIOUS AK

Sprues are milled directly at the injection moulding machine and transported back to our warehouse. In this way the correctly sorted mill materials are available to us as recompounds for various applications. Mill materials that cannot be re-used in our own production are sent to recycling companies. The waste heat that is created in the injection moulding process is used to heat our entire building and is thus re-used in an environmentally friendly and sustainable manner.

MATERIALS

Re-use of granulate residues and molten granulate

ENERGY

The more effective use of existing energy saves our environment. This is why we have installed the most modern technology in order to be able to use waste heat from production more effectively.

Underfloor heating was fitted throughout our production halls for the effective heating and temperature regulation of our operation.

The more effective use of existing energy saves our environment. This is why we have installed the most modern technology in order to be able to use waste heat from production more effectively.